Profile:

High frequency voltage doubling circuit, PWM pulse width modulation technology and high power IGBT device are used.

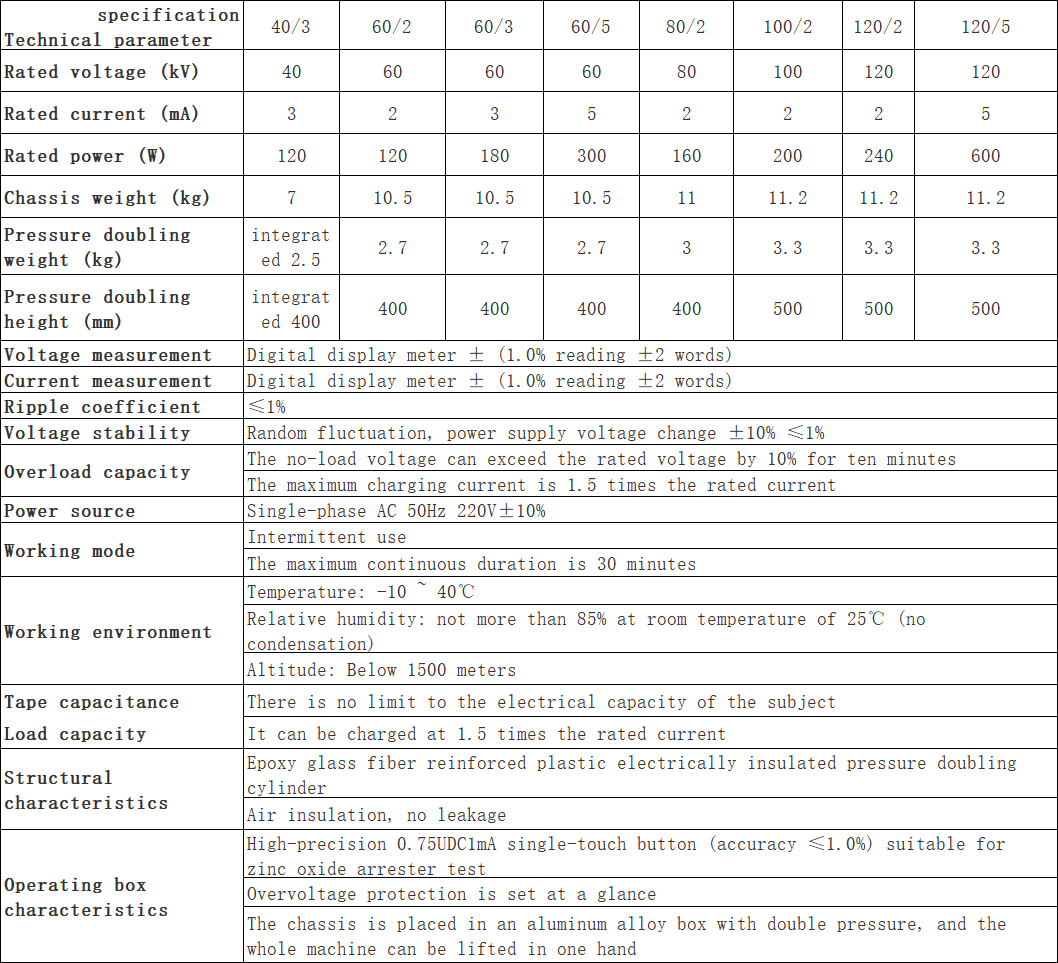

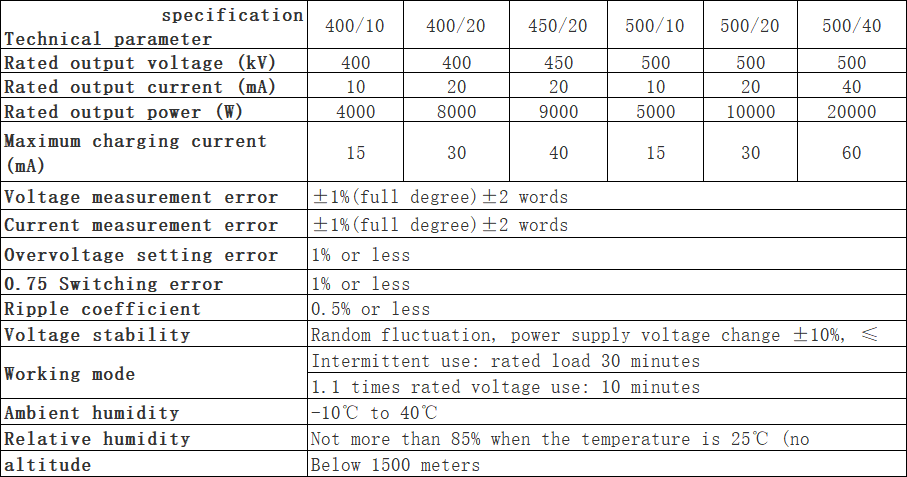

With large voltage feedback, the output voltage stability is high, and the ripple coefficient is less than 1%.

Range smooth voltage regulation, voltage regulation fineness good adjustment accuracy ≤0.5%, stability ≤1%, voltage and current error 1% (reading ±0.2KV), current error ±1 word.

Features:

Product features:

● High frequency voltage doubling circuit, PWM pulse width modulation technology and high power IGBT devices.

● Large voltage feedback, high output voltage stability, ripple coefficient ≤1%.

● Range smooth voltage regulation, voltage regulation fineness good adjustment accuracy ≤0.5%, stability ≤1%, voltage and current error 1% (reading ±0.2KV), current error ±1 word.

● Zero voltage boost potentiometer.

● 75%UDC1mA function button, convenient zinc oxide arrester test, accuracy 1% reading ±1%.

● Overvoltage protection using code setting, clear at a glance, error ±1%.

● Pressure doubling using new materials, light and strong. Appearance coated with special insulation material, good electrical performance, strong moisture resistance.

● Folding support foot, large diameter area, good stability.

● Integrated design, high voltage mop cable leading, convenient field test.

● The products meet the technical requirements of DL/T848.1-2004, and have passed the type test of the electrical equipment quality testing center of the Ministry of Power, and strictly implement the enterprise standard factory.

1, liquid crystal display: 320*240 dot matrix LCD, display a variety of setting parameters, test status, results, prompts and so on.

2, printer: used to print out the test results.

3. Power switch: control the power supply of the whole machine.

4, control knob: used to set parameters and adjust voltage.

5, high voltage open indicator light, button: red, with indicator button. On indicates that the current high voltage is enabled, and the high voltage can be output or has been output. In the status interface, when the green light is on, press the red button, the red light is on and the green light is off, indicating that the high voltage circuit is connected, and the voltage test can be boosted at this time.

6. Timing button: yellow, timer trigger button. After pressing this button, the timer starts to count from zero.

7, high voltage off: when the red light is on, press the green button, the red light is off and the green light is on, and the high voltage circuit is cut off.

8. Ground terminal: This ground terminal is connected to the ground terminal of the voltage doubling cylinder and the test product at one point, and then connected to the ground network. Use the ground cable group provided with the device.

9, high pressure measurement: for the control box and pressure doubling unit measurement connection. The high voltage is fed to the control box via a special three-core cable. When connecting, just turn the red dot on the cable plug to the red dot on the socket in the clockwise direction, and turn the cable plug in the opposite direction when disconnecting the cable.

10, Connect the optical fiber: used to connect with the high-voltage microammeter, so as to import the high-voltage current value of the microammeter into the host display.

11, high frequency output: used for control box and voltage doubling unit high frequency connection.

12. Power input socket: Connect with the power supply with the power cord randomly equipped. Power supply type: AC 380V, three-phase three wire.

13, communication port: for online communication with the computer (host computer).