![Kaidi Zhengda has overcome the faults of copper-aluminum hybrid cables, demonstrating its profession]()

28 May-2025

Recently, Wuhan Kaidi Zhengda Electric Co., Ltd. successfully and precisely located a fault in a 300-meter-long 10kV high-voltage cable at a certain management office of Hubei Jiaotou E Dong Expressway Company. Due to the special material and complex laying path of the faulty cable this time, the previous two rounds of personnel's investigation failed. Relying on professional equipment and years of experience, Kaidi Zhengda finally quickly located the fault point, demonstrating its industry strength.

This cable adopts a segmented structure of copper core and aluminum core. Although this design reduces the cost, it brings challenges to troubleshooting. The electrical conductivity of copper and aluminium differs significantly (1.72×10⁻⁸Ω·m for copper and 2.82×10⁻⁸Ω·m for aluminium), which leads to the easy distortion of fault signals during transmission. Technicians need to capture the signal distortion points through the high-frequency pulse reflection method and combine the physical properties of copper and aluminum to precisely locate them. This material property not only increases the difficulty of signal analysis, but also requires technicians to have rich experience and acute judgment.

The cable laying path crosses mountainous areas, expressways and buildings, and the environment is complex and changeable. Technicians need to combine topographic maps with real-time test data.

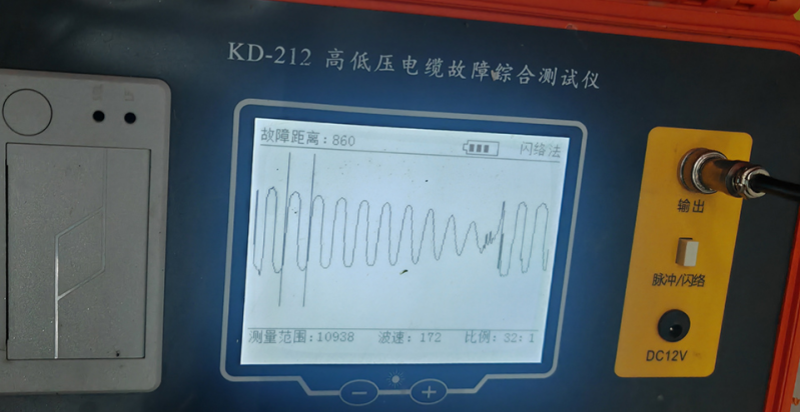

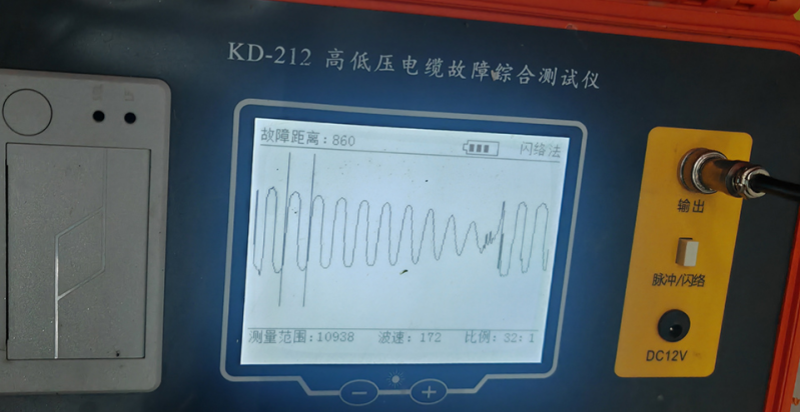

Facing this technical challenge, Kaidi Zhengda dispatched an experienced technical team and carried self-developed equipment such as the KD-212 Cable Fault Comprehensive tester and the insulation resistance tester. Among them, the KD-212 cable fault tester can conduct comprehensive analysis and detection of faults such as poor grounding contact of high and low resistance in underground power cables, mining cables, communication cables, street lamp cables, high and low voltage cables, directly buried cables, and overhead cables.

The KD-212 cable fault tester can test high-resistance flashover faults, high and low resistance grounding, short circuits, cable breakage, poor contact and other faults of cables. At the same time, it can be used to test the fault distance of power cables on main lines above 35kv. The cable fault tester is equipped with a sound measurement point tester, which can accurately determine the precise fault location of the fault point. This power cable fault tester is particularly suitable for testing power cables and communication cables of various models and different voltage levels.

Before Kaidi Zhengda Electric took over this fault, two groups of personnel from the power company and the user themselves had conducted fault searches, but neither could successfully locate the fault point. This situation further highlights the complexity of the current cable failure problem. After a long period of efforts by two groups of professionals, the problem still failed to be solved, indicating that this fault is not only highly concealed but also difficult to troubleshoot.

Under the meticulous operation of the technicians, the KD-212 Cable Fault Comprehensive tester successfully captured the fault signal and accurately pointed out the location of the fault point. Ultimately, the technicians successfully located the fault point. It demonstrates its professional strength. In the face of various complex cable faults, Wuhan Kaidi Zhengda can still quickly and accurately locate the fault point.