31 Jul-2025

product overview

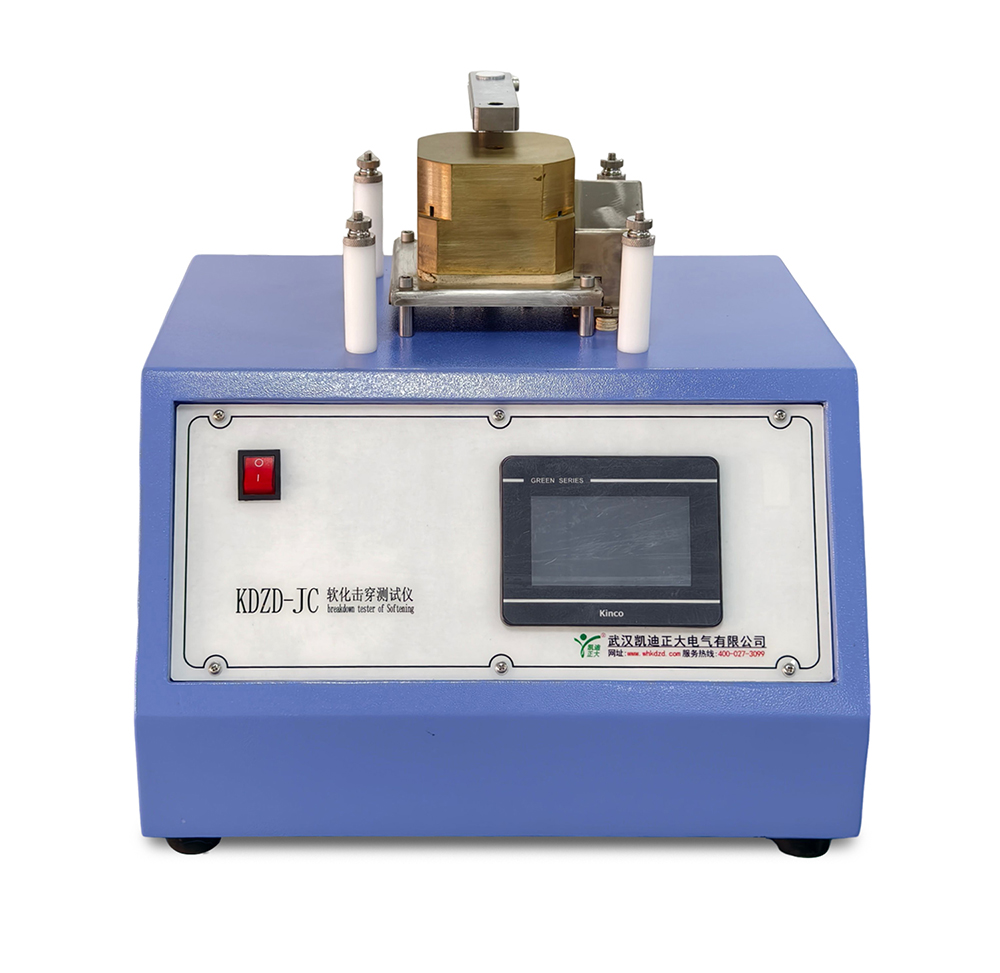

The KDZD-JC softening breakdown tester follows the standard GB/T4074.6-2008/IEC 60851-6; Inspection standard: JB/T4279.8-2008, suitable for testing the insulation performance of enameled round wires and thin film wrapped round wires with a nominal diameter of 0.020mm to 3.000mm and below, as well as flat wires with a diameter of 10mm to 2mm and below, after softening in a hot state. The instrument can automatically measure, control, adjust and display temperature; According to the set preheating time, target temperature, and test time, the instrument automatically completes the preheating of the sample, applies load, and test voltage. When the test time is reached or the sample is broken down, it automatically unloads the load and alarms, and displays the test time and temperature. The entire testing process is automatically completed.

TECHNICAL INDEX

Heating mold size: 100 × 100 × 70mm

Heating mold two wire groove intersection angle: 90 °

Applicable circular wire specifications: diameter less than or equal to 3mm

Applicable flat wire specifications: less than or equal to 10mm x 2mm

Constant temperature method&rising temperature method - Test voltage: AC100V ± 10V

Temperature rise method 2 experimental voltage: AC155V ± 10V

Constant temperature method&rising temperature method - one sample breakdown action current: 5 ± 0.5mA

Temperature rise method, second sample breakdown action current: 20mA ± 1mA

Short circuit current between samples: < 50mA

Display temperature and temperature difference at the intersection of the sample: < 2 ℃

Sample preheating time and test time: 1 second to 999 seconds can be set arbitrarily

Maximum test temperature: ≤ 450 ℃

Input power supply: AC220V ± 10% 50Hz

Heating power: 900W

Dimensions: L × W × H 450 × 380 × 500mm

Weight: 30kg

As a high-precision instrument for professional testing of insulation performance of enameled wire, KDZD-JC softening breakdown tester has intelligent design, precise temperature control technology, and multi scenario applicability

By preset preheating time, target temperature, and test time (adjustable from 1-999 seconds), the instrument automatically completes the entire process of heating, pressure application, and alarm without manual intervention. When the sample breaks down, the load is automatically unloaded and an audible and visual alarm is triggered, while recording the test temperature and time data.

Supports two testing modes: constant temperature method/rising temperature method one (AC100V ± 10V, 5 ± 0.5mA) and rising temperature method two (AC155V ± 10V, 20 ± 1mA), to meet the insulation performance testing requirements under different standards.

Using PID algorithm to ensure that the temperature difference between the heating mold (100 × 100 × 70mm) and the intersection point of the sample is less than 2 ℃, avoiding testing errors caused by temperature fluctuations in traditional equipment.

Supporting a maximum test temperature of 450 ℃, it can simulate the performance of enameled wire under extreme heat conditions, providing a rigorous verification environment for product quality.

Compatible with enameled round wire with a diameter of 0.020-3.000mm, film wrapped round wire, and flat wire below 10mm × 2mm, covering the vast majority of industrial wire specifications.

The short-circuit current is limited to within 50mA, and in conjunction with the insulation groove body (90 ° angle between the two wire grooves) and overcurrent protection mechanism, it ensures the safety of operators and equipment.

The digital screen provides real-time feedback on key data such as temperature, time, and current, making the test results clear at a glance.

The 450 × 380 × 500mm body (only 30kg) saves laboratory space, and the 900W heating power balances energy efficiency and heating speed.

Compliant with authoritative standards such as GB/T4074.6-2008, IEC 60851-6, and JB/T4279.8-2008, the test data has global recognition.

Aluminum alloy molds and reinforced body structures can withstand long-term high-frequency testing, reducing maintenance costs.